Meet the Blade. It goes from zero to 60 in 2.5 seconds, boasts 700 horsepower, and has a top speed that is totally illegal. Typical sports car stuff.

That’s where the similarities end. The Blade weighs just 1400 lbs — less than half a typical two-seater — and its lithe frame can zip around on mere sips of compressed natural gas. Most important, it is built using low-energy 3D printing technologies. A product of the Silicon Valley mindset, it very much wants to change the world.

The Blade was dreamed up by Kevin Czinger, CEO of Divergent Technologies, a Los Angeles-based automotive startup. Mile for mile, Czinger says, a car that’s 3D-printed like the Blade will inflict one-third the environmental damage of an electric SUV such as the new Tesla Model X. “If we only build 5000 lb SUVs, we will destroy the planet,” says Czinger. “We have to build lighter, more efficient cars.”

It’s easy to see the exhaust belching from a pick-up truck and assume that’s the biggest problem to fix. But Czinger contends we’re spending too much time worrying about tailpipes when we should be rethinking the whole production process. Less than a third of the environmental damage from traditional motor vehicles comes from fueling and driving them, according to a 2009 National Academy of Sciences report that Czinger likes to cite. The rest comes from the process of manufacturing a vehicle: physically pulling all that metal from the ground, refining it, moving it, cutting, drilling and stamping it into chassis and panels.

Electric vehicles can be particularly harmful to manufacture, according to the report, requiring about 20% more energy and emissions than their gasoline-powered counterparts. Their batteries use metals like cobalt and lithium that are energy-intensive to extract and refine (and sometimes come from conflict areas), the manufacturing process can expose workers to toxins, and recycling is a complex affair. Once you account for the full life cycle, suddenly the Teslas, Leafs and Volts of the world look a shade less green.

By the middle of the 21st century, Earth will probably be home to an extra two and a half billion people, and twice as many more road-hogging, carbon-pumping cars. Little surprise, then, that tech companies such as Google and Apple, as well as a host of start-ups, are scrambling to offer their vision of our transportation future, usually with some tech-enhanced environmental or safety angle.

For Kevin Czinger, the path ahead is obvious. “The leverage point for dramatically reducing greenhouse emissions from vehicles is clearly manufacturing,” he says. “We need to radically reduce the material, energy and capital costs of designing and building a car.”

Czinger is one of a small group of automotive entrepreneurs trying to reinvent the the entire car production process. They want to use 3D printers to build cars with a fraction of the carbon footprint of traditional assembly lines, using designs that can vary from hour to hour, and incorporating new self-driving technologies the moment they become available. Along the way, they hope to boost employment across the country, reduce road deaths and unleash an explosion in creativity that will vastly increase the variety of vehicles on our roads.

You have to be willing to dream a little to see the full beauty of their ideas, but that doesn’t mean they’re all talk. Czinger is offering rides in a 3D-printed Blade today, and Jay Rogers, CEO of Local Motors, is road-testing a 3D-printed car his company only finished designing in August. “History would tell us that the creative disruption process will rip like a hot knife in butter through the most inefficient parts of the industry,” says Rogers.

To understand Silicon Valley’s latest salvo against Detroit, it makes sense to go back to where it all began.

In1909, at the dawn of the automotive age, it took 12 hours to laboriously piece together a single Model T. Then Henry Ford hit upon the concept of the moving assembly line, where semi-assembled cars move smoothly from one work station to the next. By 1914, Ford’s assembly lines could fabricate a Model T in 90 minutes. Quality rose and prices tumbled, opening up individual transportation for the masses. Today, America’s most popular vehicle, the Ford F-150 pickup, streams out of factories in a never-ending blur of metal, glass and plastic, 800,000 strong each year.

That pace relies on one concept: that every manufacturing process, no matter how complex, can be carried out most efficiently when split into simple, repeatable tasks. Weld this bar to that panel. Place this lamp into that fixture. Wire this unit to that junction. Next!

A modern car typically has around 20,000 individual components, assembled by a choreographed symphony of machines each dedicated to a single function (plus a few humans for oversight and servicing). But building a car factory from scratch might take five years and cost a billion dollars, and even tweaking one to manufacture a new vehicle is phenomenally expensive — over $200 million according to one estimate for Volkswagen.

This is the opportunity these car entrepreneurs are seizing, by developing a process known as additive manufacturing. It means building something all at once from its constituent materials. You’ve probably seen 3D-printed jewelry or knick-knacks, made in desktop MakerBots by heating plastic wire and extruding it layer upon layer like toothpaste.

The process can create complex and quite beautiful structures that surpass the work of traditional molds or hand carving. But it took one imaginative Canadian tractor designer to apply 3D printing to the automotive industry. Jim Kor, an avuncular bearded engineer from Winnipeg, is credited with making the first vehicle body using additive manufacturing.

Kor had long dreamed of making a hyper-efficient pod-like car called the Urbee. In 2007 he got the nudge he needed: the launch of what came to be known as the Progressive Insurance Automotive X Prize, a $10 million competition to build production-ready cars capable of achieving 100 miles to the gallon. Drawing on his background in farm equipment, Kor plunged into the challenge as he had with tractor designs in the past, by making a 60% scale clay model. He got the model digitally scanned so he could run aerodynamic simulations, and then planned to laboriously hand-carve the car’s body from foam and wood or using pricey computer-controlled milling machines.

Instead, a chance meeting with engineers at additive manufacturing pioneers Stratasys prompted Kor to consider 3D-printing the body out of a general-purpose plastic, called ABS, used in products as diverse as drainage pipes and kayaks and car bumpers. “When I saw the size of the parts Stratasys could print, I thought, let’s try it one time,” he says. The ABS panels fit together perfectly straight out of the printer.

Building a tiny pod-like car was one thing, but if 3D printing was going to be really useful, it would have to produce much larger vehicles.

Enter Jay Rogers and Local Motors. Rogers was already disrupting automotive production by bringing crowdsourcing to car design. His company’s first vehicle, a snarling, post-apocalyptic (but street legal) muscle car called the Rally Fighter, was the fruit of 500 volunteers working together online to design everything from its styling to its suspension. Rogers and a small team of automotive engineers would tell the crowd that the car needed, say, a headlight housing, and the team would later judge the responses.

The vehicles were assembled one by one in low-volume workshops called ‘microfactories.’ The company’s 40,000 square-foot pilot microfactory in Phoenix, for example, looks like a cross between a garage, a factory and a classroom. Vehicles are individually assembled by a team of mechanics — with help from the car’s eventual buyer. Such a painstaking, artisanal way of working means the microfactory can produce only around 100 Rally Fighters a year, each with a $100,000 price tag. In addition to the Phoenix site, Local Motors says it is about to open another microfactory in Knoxville, and up to 50 more microfactories and smaller labs in the next five years.

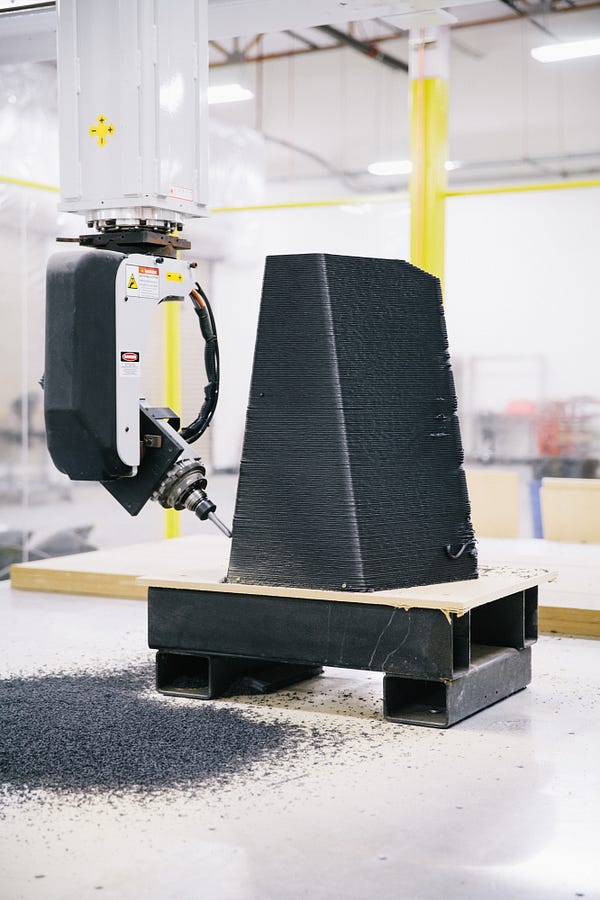

Rogers realized that 3D printing might, eventually, boost his production speed while reducing costs. So in 2014 Rogers began work on his first experimental 3D-printed car, the Strati, with the help of Oak Ridge National Laboratory in Tennessee (ORNL) and Cincinnati Incorporated, a tool-making company. Cincinnati Incorporated had developed a technology called big area additive manufacturing (BAAM) that uses the same approach as home 3D printers: melting ABS plastic, here infused with chopped carbon fiber for strength, and laying it down in precise layers. But where MakerBots are limited to desktop ornaments, BAAM can print items 20 feet long, 8 feet wide and 6 feet tall — large enough to print almost an entire Strati in one go.

“The additive process allowed us to combine a lot of things into one part,” says Lonnie Love, leader of the manufacturing systems research group at ORNL. “We went from the 20,000 parts you might find in most cars down to about 50.” Once the body was printed, the remaining components — such as an electric motor, batteries, wheels, lights, seats and controls (mostly made traditionally) — could be quickly mounted manually.

With experience they’re becoming faster. When the Department of Energy recently asked ORNL to build a follow-up vehicle, Love and his team designed and 3D-printed an all-electric replica of a classic Shelby Cobra sports car in just six weeks. “Six weeks from saying let’s print a car to having a working vehicle is unheard of. Six weeks is insane,” says Love.

The printing itself is accelerating, too. They went from putting down 10 lbs of material an hour and six days to print a Strati in the summer of 2014 to 40 lbs an hour and a printing time of 2 days. A year later, BAAM is running at close to 100 lbs an hour, fast enough to produce a car in less than seven hours.

The quicker a car can be printed, the less it costs. A BAAM machine costing half a million dollars works out to an hourly bill of around $100. Add in 500 lbs of carbon fiber-reinforced thermoplastic at $4 a pound and ORNL can print a Shelby Cobra for under $3,000 (note: you’ll still have to pay for wheels, seats, drivetrain and a sharp retro paint job). A replica Cobra made traditionally costs upwards of $40,000.

Divergent is using different technology to additively manufacture the Blade supercar. Instead of printing the whole external body out of ABS like the Strati, a process that Czinger says makes for a very heavy car, Divergent is assembling the Blade’s interior skeleton from carbon fiber tubes connected by 3D-printed metal brackets called nodes.

The nodes are formed by powerful lasers sintering powdered metal into customized shapes, and the tubes are then simply slotted in by hand. With all the strength and crash protection embodied in the tubes and joints, the exterior panels can be made, Divergent claims, from almost any lightweight material, even paper.

Simply by changing the software, the same machine can print both a sports car and a minivan, Czinger says. “These structures can be very quickly assembled in a modular way to build anything from a two-seater to a pick-up truck… and do it at fraction of the capital cost of what hard metal tooling and stamping require.”

Divergent hopes to start taking orders for the Blade next year and deliver cars as soon as 2017. Local Motors is equally ambitious, announcing earlier this month that its first 3D-printed production car, the LM3D, will go on sale in early 2017 for around $53,000.

Love’s experience with the Shelby Cobra gave him an epiphany: “Local Motors is more innovative than they realize. They’re not just eliminating the automotive manufacturing facility, they’re radically changing the whole supply chain.” Love notes that a car dealership typically costs a few million dollars and is physically around the same size as Local Motors’ Phoenix microfactory. Why not combine the two? A customer could come in, sit down with an engineer, design their car, and have it printed in a couple of days.

The overthrow of a fully globalized, century-old, $9 trillion industry is fraught. Shrinking cars from 5000 lbs to 1400 lbs raises important safety issues that have yet to be fleshed out. Scaling up and speeding up 3D printing to become something more than a sideshow is an unsolved problem. And no one is really sure whether 3D printing at scale will be much greener than existing techniques. (Laser sintering, for example, uses about 40 times more energy per kilogram than aluminum metal working in mass production.) A regulatory tousle also awaits the first carmaker to update their car on the fly.

When I describe the idea of collecting your next car from a local printer to Mark Stevens, a manufacturing expert at the nonprofit Center for Automotive Research, in Michigan, he bursts out laughing. “The idea that you can print a car on demand! It’s not going to happen in our lifetimes,” he says. His problem is with how it might scale. “A traditional assembly line could make a hundred vehicles while they print one.”

Divergent’s Kevin Czinger acknowledges that “our single biggest challenge is getting carmakers to work with us.” He hopes to sign a joint development agreement with a major car manufacturer next year for a new vehicle, much more mainstream than the Blade, to sell 10,000 or so a year.

The fate of the Urbee — Jim Kor’s diminutive podcar — may be instructive here. His small firm was unable to hit X Prize deadlines and ended up dropping out of the contest. When he did finish the Urbee, the two-seater electric/ethanol hybrid blew past X Prize goals, achieving around 200 mpg on the highway. The organizers of the X Prize were so taken that they pushed Kor to start a company. But after chasing funding for a year, he couldn’t raise the money he needed. Kor now thinks the best way to get Urbee onto the market is to license his designs to other manufacturers.

Local Motors’ Jay Rogers, meanwhile, would like to emulate Apple’s new iPhone upgrade program, where users pay a fixed monthly fee for access to the latest handsets. “We’re going to change these devices so fast that it’s better if you don’t have customers thinking of them as owning them,” he says. “I want to be the first person to put an autonomous vehicle on the road for customers to buy. Then the next month I want to have the next sensor that will make it even better. And the next month I want the next battery, and on and on and on.”

There is an obvious problem with this. As much as additive manufacturing might shorten production times, cut emissions and costs, and eliminate heavy machinery, cars are not reducible to software. There is a large physical presence that has to function efficiently and safely over many years in the real world. If a windshield wiper fails or a poorly-designed battery overheats, you can’t update them over the air.

How, for instance, might a small, distributed company like Local Motors develop something as complex as self-driving systems, and then keep them working perfectly on a range of vehicles, no two of which might be exactly alike? Rogers, true to form, suggests turning to the crowd: “What if I give a hundred people in my community the first version of these cars, and challenge them to help me develop faster?” he says. “We’ll say to the community, develop the crash avoidance software at the speed Waze developed traffic avoidance software versus Google Maps.”

In return, users might get gamified incentives like points or early access to new vehicles. They might even receive a payment if the car sells well, although Rogers insists that he will “invoke Wikipedia rules instead of Google money. We will give you pride.”

How regulators might respond to automotive software developed under the Wikipedia ethos is also up for debate. “Companies still have to solve the problem of how to make every car different and yet all of them proven to be safe,” says Lonnie Love. “I can’t predict when that will happen. It could be 5 years from now, it could be 50.”

But if there’s one thing that Silicon Valley likes, it’s an idea that starts small and cheap, annoys regulators, and harnesses the power of the crowd. Building a car factory today is a multi-billion dollar, once-a-decade decision for a multinational. Setting up a $20 million microfactory in the future might require nothing more than some innovative vehicle designs, a few entrepreneurs and a hefty bank loan. Car production could become local — think many mini-Detroits — serving purely local needs.

“Playing in the gaps between the product lines of major manufacturers isn’t a limitation but a liberation,” says Rogers. “Making several thousand units a year at a microfactory becomes meaningful because if you can make money and make happy customers doing it, you can engage a whole community.”

Traditional car makers are also slowly waking up to the benefits of 3D printing, initially to replace factory tools and fixtures made from expensive, resource-hungry metal. Luxury marques like Mercedes, Cadillac and Lexus were quietly working on automated driving systems like adaptive cruise control and lane departure warnings for years, only to have their thunder stolen by self-driving upstarts from Google and Tesla. The automotive industry is keen not to get left in the dust again.

Meanwhile, additive manufacturing is evolving at Silicon Valley clock speeds. If 3D printing technologies continue their rapid improvements in speed, cost and energy usage, if new software tools can democratize design and testing, and if regulators and the public embrace the coming Cambrian Explosion in vehicle diversity — many if’s, to be sure—the result will be an epic confrontation.

The advocates of 3D-printed cars return time and again to the argument most compelling to them: that additive manufacturing can be an order of magnitude more energy-efficient than traditional practices. That alone might drive its adoption, though its benefits are not only in being less bad. A drop in production efficiency is offset by a gain in the pace of invention. It can only be a matter of time before we see the first Kickstarter for a passenger car. “I think a whole industry can be built up around rapid innovation in transportation,” says Love. “And that is revolutionary.”

via:medium.com