Porsche is 3D printing electric drive housings that are lighter and more stronger than ordinary ones

In December, Porsche declared that it had been 3D printing prototype housings for electric drives that were more stronger, lighter, and a lot faster to produce. The engine-gearbox units delivered utilizing this technique were even ready to pass the entirety of the company’s quality and stress tests without issue.

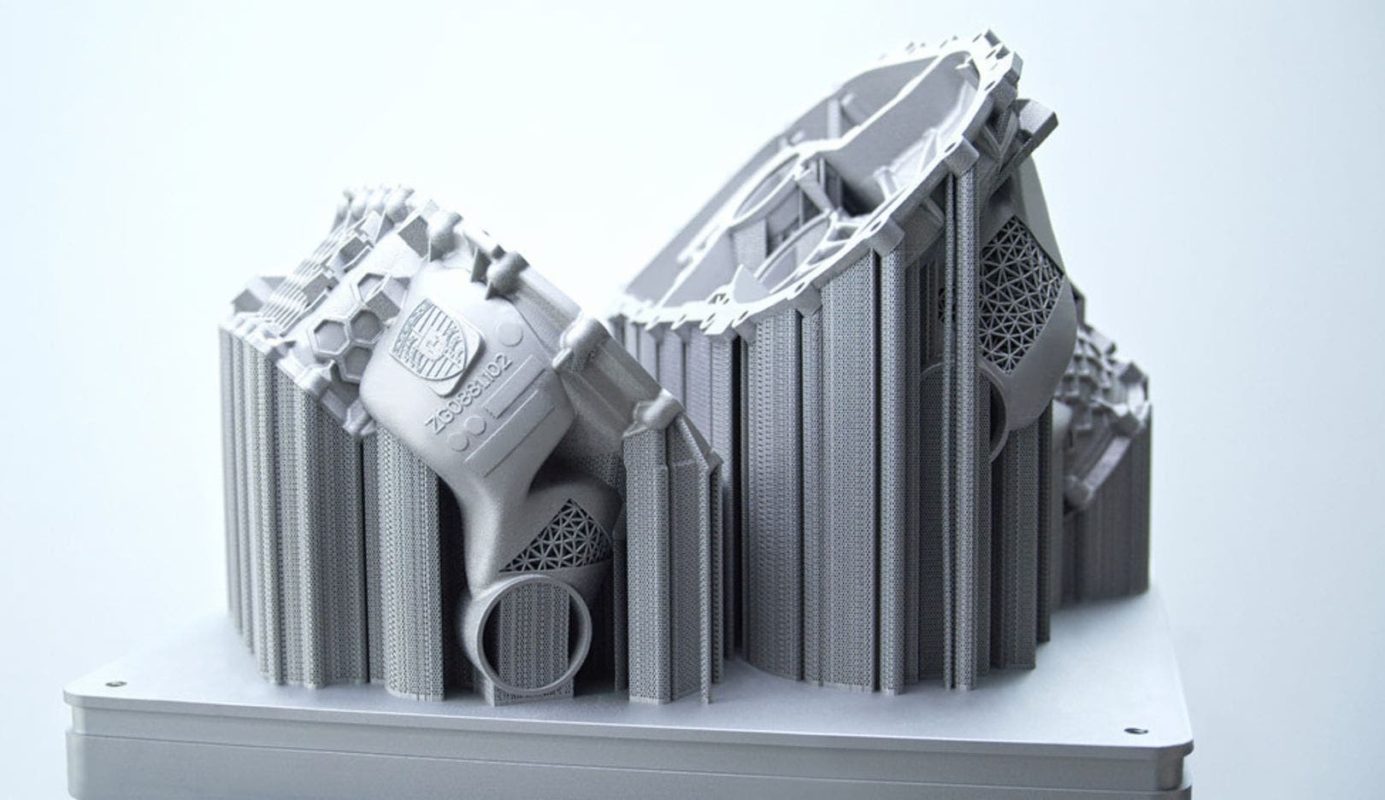

Porsche manufactures the housings utilizing a 3D printing strategy called laser metal fusion, which involves a laser beam heating and melting a powder surface depending upon the ideal contours. This technique allows Porsche to deliver a engine gearbox that is both 10% lighter and 100% stronger because of the inherent lattice structures.

Another huge potential gain to manufacturing parts this way is the simplicity and speed of making new components or making changes to existing ones. For instance, a totally new part can be designed and afterward truly printed rapidly with no compelling reason to do things, for example, make new tooling to manufacture the part.

Frank Heilfort, project manager in the Powertrain Advance Development department at Porsche said, “this demonstrates that additive manufacturing with every one of its preferences is additionally reasonable for bigger and exceptionally focused on components in electric sports vehicles.” Heilfort even ventured to say that electric drives with 3D printed parts could be utilized later on for limited-edition super sports cars.

Implementing 3D printed parts into Porsche’s electric vehicles, for example, the Taycan and impending all-electric Macan bodes well while considering their hefty load because of the battery packs. For example, the Porsche Taycan 4S tips the scales at 5,128 pounds, which is around 2,000 pounds heavier than the Spyder. Having the capacity to rather 3D print a couple of the heavier pieces of the vehicle would chop down the curb weight, possibly extracting more performance from it.

Porsche additionally says that there is potential for it to start producing obscure spare parts utilizing 3D printing for older vehicles that are done being created. The organization additionally expressed that it could start to create customization parts that appeal to a more specialty client base without the immense expenses ordinarily connected with such a move. The prospects this manufacturing method unlocks could genuinely be perpetual.

For more news and updates, visit WHEELive.

Start the discussion at forum.wheelive.com